The industrial landscape is rapidly transforming as robotics and automation become central to manufacturing competitiveness. However, the success of robotic implementation doesn’t solely depend on advanced hardware – it fundamentally relies on having skilled operators who can maximize these systems’ potential. As companies invest millions in robotic infrastructure, the critical question becomes: How do we ensure our workforce is prepared to operate these sophisticated systems effectively?

Modern Requirements for Robotic System Operators

Today’s robotic operators need far more than basic machine operation skills. The modern operator profile includes several critical competencies:

Technical Programming Skills

Operators must understand robot programming languages, trajectory planning, and coordinate systems. They need proficiency in both online and offline programming of robot systems, allowing them to adapt quickly to different operational scenarios.

Kinematic Understanding

A deep comprehension of robot kinematics, joint limitations, and workspace boundaries is essential. This knowledge prevents costly collisions and ensures optimal robot performance across various applications.

Digital Interface Mastery

Modern robotic cells integrate multiple systems requiring operators to navigate complex HMI interfaces, interpret diagnostic data, and manage automated workflows efficiently.

Key Insight: The most successful robotic operators combine technical knowledge with problem-solving abilities and safety consciousness.

Types of Training Programs and Their Characteristics

Theoretical Foundation Courses

These programs cover fundamental robotics principles, safety protocols, and system architecture. Typically lasting 40-80 hours, they provide the conceptual framework necessary for advanced training.

Hands-on Practical Training

Real-world application training using actual robotic systems allows operators to develop muscle memory and confidence. These intensive workshops typically span 1-2 weeks with direct equipment interaction.

Online Learning Platforms

Digital training modules offer flexibility for busy production schedules. Interactive simulations and virtual labs enable learning without disrupting operations or risking equipment damage.

Certification Programs

Industry-recognized certifications validate operator competency and often serve as career advancement tools. Programs typically include both theoretical assessments and practical demonstrations.

Innovative Training Methodologies

Virtual and Augmented Reality Integration

VR/AR technologies are revolutionizing operator training by creating immersive, risk-free learning environments. Trainees can practice complex procedures, experience failure scenarios, and develop expertise without equipment downtime.

Digital Twin Training Systems

Advanced companies utilize digital twins of their robotic cells, allowing operators to train on exact replicas of their production environment. This approach ensures training relevance and accelerates skill transfer to real operations.

Gamification Elements

Modern training incorporates game-like elements including:

- Progress tracking and achievement badges

- Competitive leaderboards among trainees

- Scenario-based challenges with increasing difficulty

- Immediate feedback and reward systems

These methodologies significantly improve engagement and knowledge retention compared to traditional classroom approaches.

Organizing Training Processes at Manufacturing Facilities

Phased Implementation Strategy

Successful training programs follow a structured progression:

- Safety fundamentals and basic robot operation

- Programming basics and simple task execution

- Advanced operations including troubleshooting

- Specialized applications specific to production requirements

Continuous Learning Framework

Technology evolves rapidly, making ongoing education essential. Companies should establish:

- Monthly skill updates and refresher sessions

- Cross-training opportunities across different robot types

- Mentorship programs pairing experienced with new operators

- Regular competency assessments and certification renewals

Success Through Strategic Investment in Human Capital

The transformation of manufacturing through robotics ultimately depends on human expertise. Companies that invest comprehensively in operator training consistently achieve higher ROI from their automation investments, reduced downtime, and improved product quality.

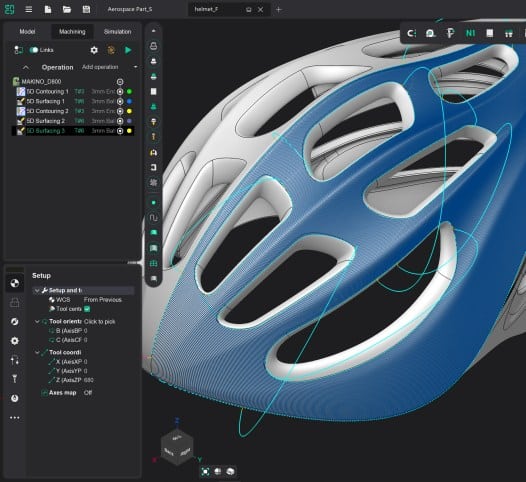

ENCY Software represents an excellent example of a developing company that understands this principle. By providing comprehensive CAD/CAM solutions alongside robust training support, ENCY has helped numerous manufacturers successfully transition to robotic operations. Their approach demonstrates that technology providers who prioritize operator education create lasting partnerships and drive industry advancement.

The future belongs to manufacturers who recognize that robotic systems are only as capable as the people who operate them. Strategic investment in training programs isn’t just an operational necessity – it’s a competitive advantage that separates industry leaders from followers.